Eliminating False Positives with Unified AI-Driven Inspections and Performance Analysis

In the rapidly evolving world of solar asset management, the ability to accurately monitor site health and performance is paramount. However, traditional methods often lead to false positives and unnecessary alarms, resulting in wasted time and resources. At Solar Spy, we’re changing the game by integrating more data and services into our unified platform and leveraging the power of artificial intelligence (AI) to eliminate these issues.

To watch the complete video simply click play below, or read the expanded article on this topic below:

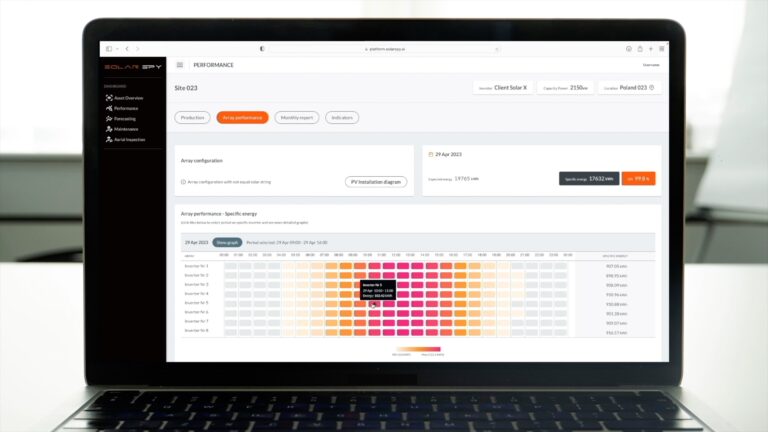

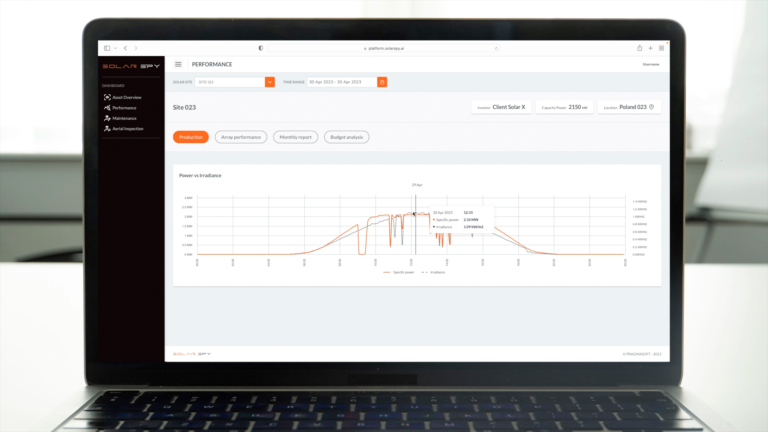

Our unified Software as a Service (SaaS) platform integrates thermal drone inspections with constant performance analysis as well as real-time meteorological data, providing an unprecedented level of insight and accuracy. This innovative approach was recently showcased in a case study, where we demonstrated how our platform can prevent false alarms and optimize solar site management.

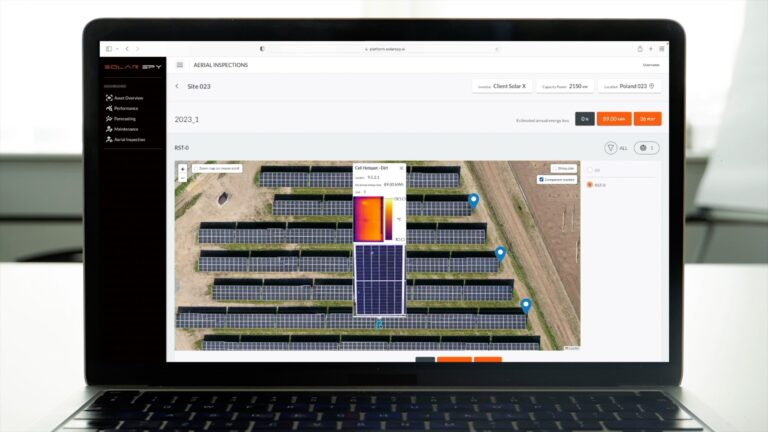

The case study involved a client with a one-year-old site that needed an independent inspection to meet warranty requirements. Using our platform, we created a 3D digital representation of the site, with every component from inverters to modules added, marked, and geo-tagged. This comprehensive map serves as the basis for creating a digital twin of the site, helping our platform make sense of the massive number of drone images snapped during the inspection.

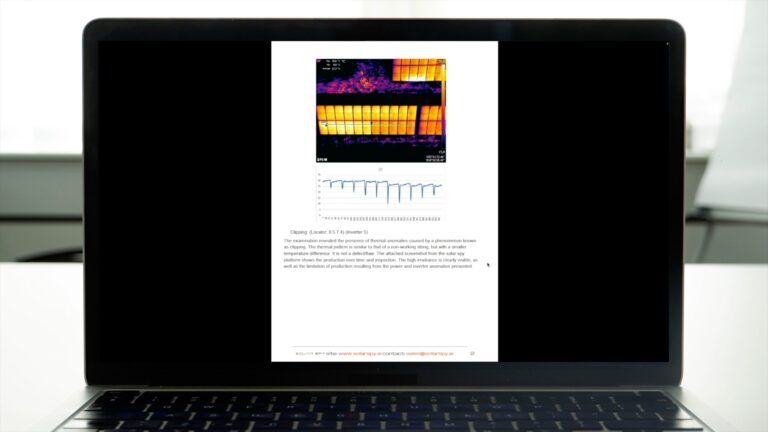

During the inspection, we did not identify any issues, apart from one dirty module that could hamper production. The interesting this was though, that as you can see in the Advanced Inspection Report below, there was in fact one string where modules were running a little hot almost to the point of being labelled disconnected string. Now if you were doing this the old-school way or even with basic AI you might be calling in a technician already, but of course, we do things differently.

Our platform digs deep to undercover root causes by pulling in direct data from inverters and keeping a constant eye on string-level performance. We nailed down the issue to a specific module on a particular string of an identified inverter.

However, instead of triggering an alarm, our platform dug deep to uncover the root cause. By pulling in direct data from inverters and keeping a constant eye on string-level performance, we were able to pinpoint the issue to a specific module on a particular string of an identified inverter.

Further analysis revealed that the suspected inverter was working fine and the issue was simply a case of inverter clipping. As a result, no manual checks were needed, no false alarms were triggered, and no technician was sent out to the site. This not only saved our client time but also significantly reduced operational costs.

This case study perfectly illustrates the power of our unified platform. By combining constant performance analysis with thermal drone inspections, we can deliver unparalleled depth of analysis and level of insights. This data-driven approach to PV asset management enables us to eliminate false positives, optimize site performance, and ultimately save our clients time and money.

At Solar Spy, we’re committed to pushing the boundaries of what’s possible in solar asset management. We believe that by harnessing the power of AI and thermal drone inspections, we can revolutionize the industry and provide our clients with the tools they need to succeed.

If you’re interested in learning more about our innovative solutions and how they can benefit your solar site, don’t hesitate to reach out. We’re always here to help and look forward to showing you what our platform can do.