Aerial Inspections with

AI-powered Analysis

Maximize asset performance with Solar Spy, combining drone inspections and AI analytics to identify, classify and prioritize defects.

Integrate with a digital twin for accurate remediation and optimized drone deployment frequency and route based on PV Copilot AI insights.

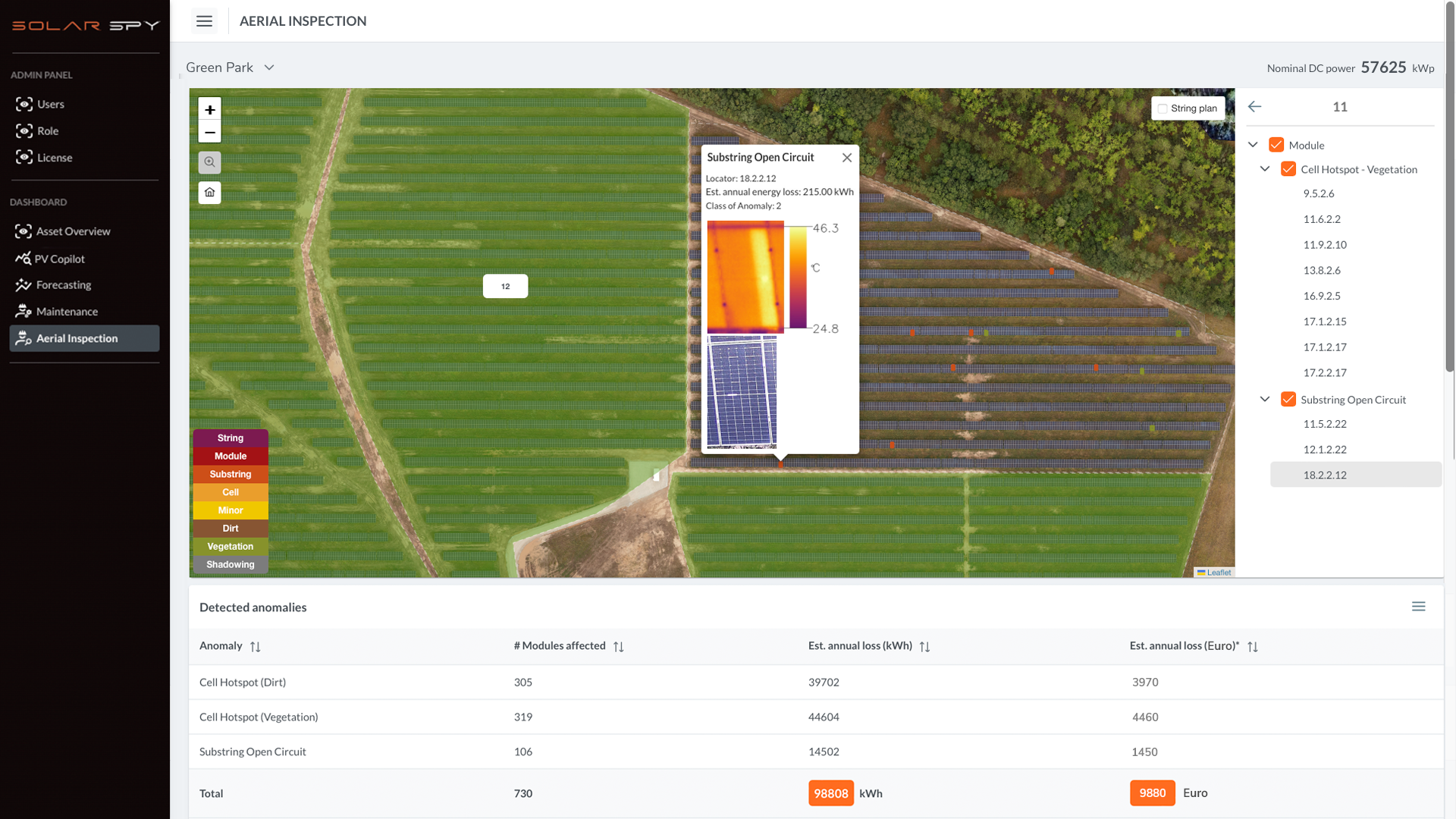

Detect, Classify, Localize & Estimate Energy Loss

Recover 5% (outliers even 18%) of lost revenue by pinpointing and addressing cell-level anomalies affecting solar output.

Monitor inter-inspection degradation to mitigate rapid deterioration or initiate warranty claims.

Implement cost-effective maintenance prioritized by impact on yield enhancement.

Hi Steven,

Multiple strings are

disconnected, likely

caused by faulty

wiring.

Needs urgent

inspection.

Click below for exact

GPS guidance.

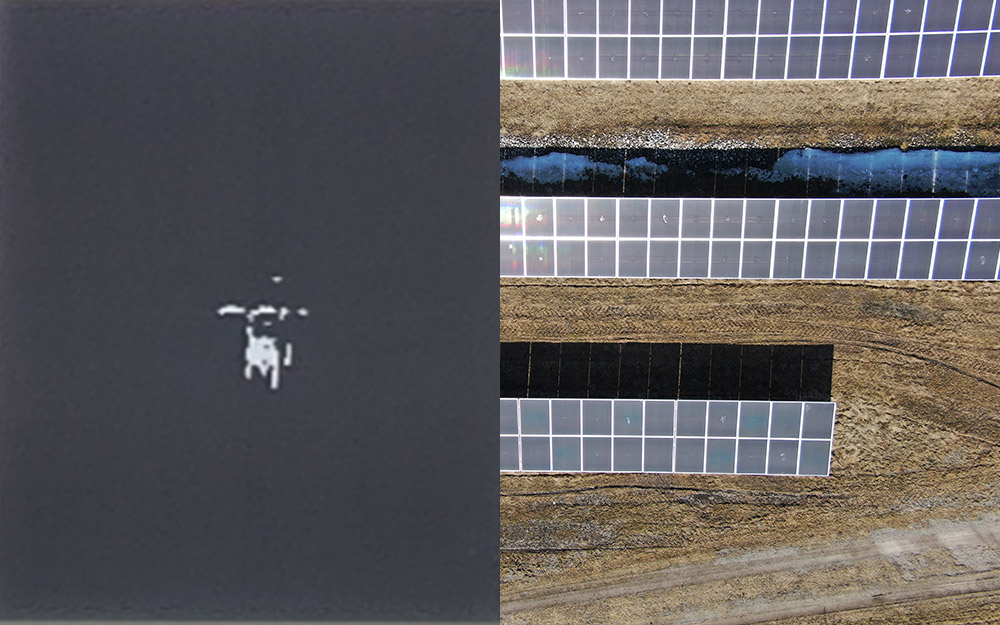

Digitize and Integrate with Digital Twins for Seamless Field Operations

- Digitize your entire solar asset portfolio for precise anomaly tracking and maintenance planning

- Support on-site teams with mobile notifications for efficient, safe remediation work and feedback

Collaborative

Inspection Process

Solar Spy cooperates with licensed trained pilots.

AI analyses images delivering detailed reports that outline specific malfunctions and their impact on energy production.

Embrace the Solar Spy Advantage: Precision and Efficiency Unmatched

- Benefit from Solar Spy's proprietary AI algorithms and dedicated team for swift, accurate diagnostics.

- Stay ahead with our deep industry expertise and compliance with the latest IEC TS 62446-3:2017 standards (certified by Solar Power Europe).

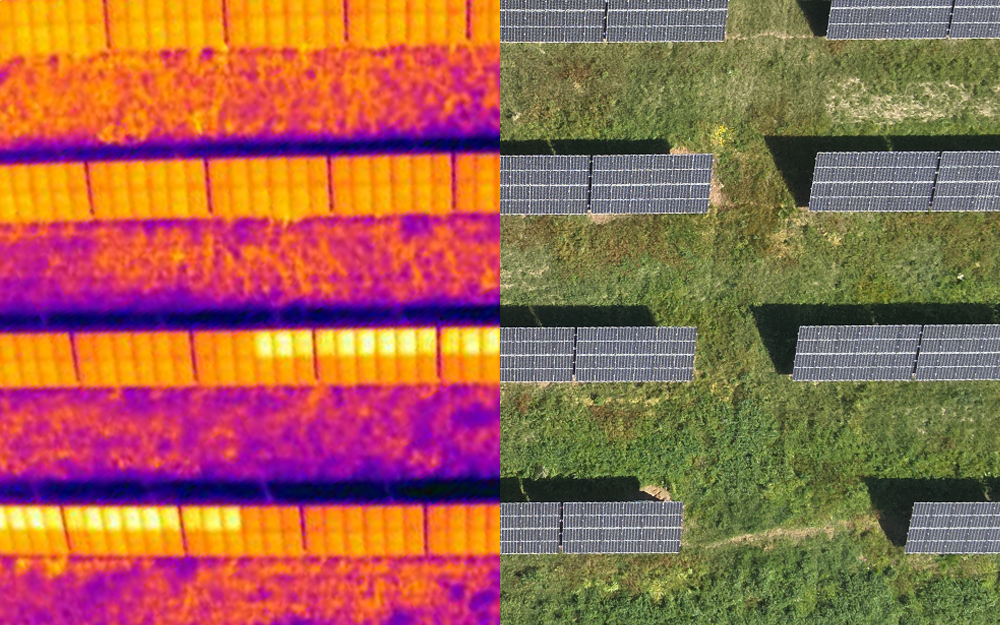

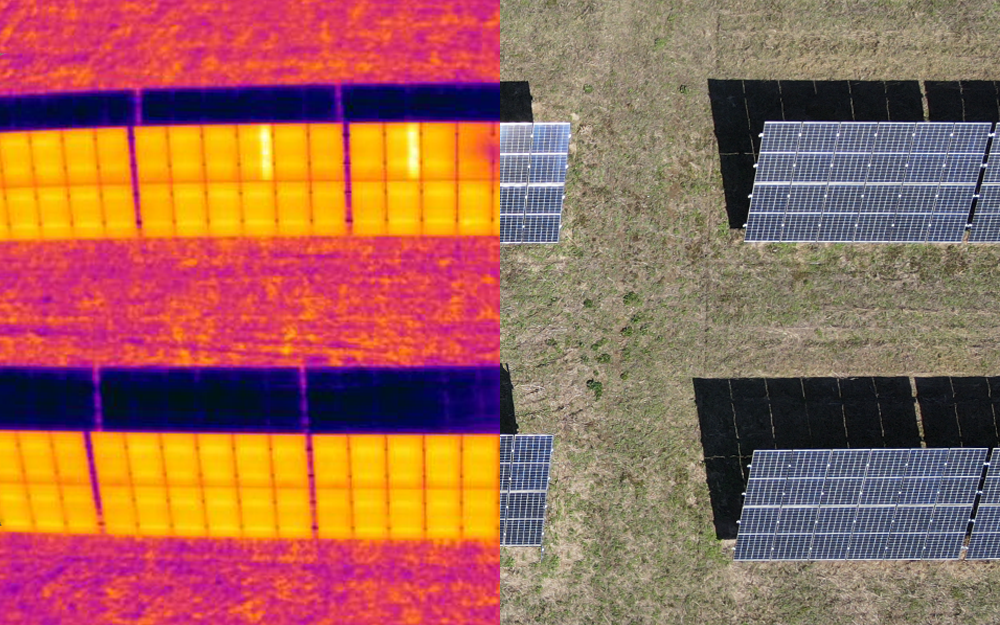

Overview Inspection

For collecting essential data on solar module health.

- Infrared imaging at 10cm/px

- HD RGB imaging at ~5cm/px

- Reliable temperature measurements

- AI prepared, human reviewed

Benefits:

- AI pinpoints offline inverters, detects string-level issues and diagnoses module-level faults that impact overall module performance.

- Ability to export data outside of Solar Spy platform in a number of formats including Excel

- Ideal for own analysis and errors correction

Standard Inspection

For detailed inspections adhering to top international technical standards.

- Infrared imaging at 5.5cm/px

- HD RGB imaging at ~2cm/px

- ITC Level 2 expert analysis and review

- AI prepared, human reviewed

- Anomaly classification based on normalized ΔT

Benefits:

- AI pinpoints cell & substring level anomalies

- Classification of anomalies based on the type of anomaly

- Location of anomalies – coordinates, position in the table, row and column

- Visualization of anomaly locations on a map or string plan

- Measurement of temperature difference for each anomaly

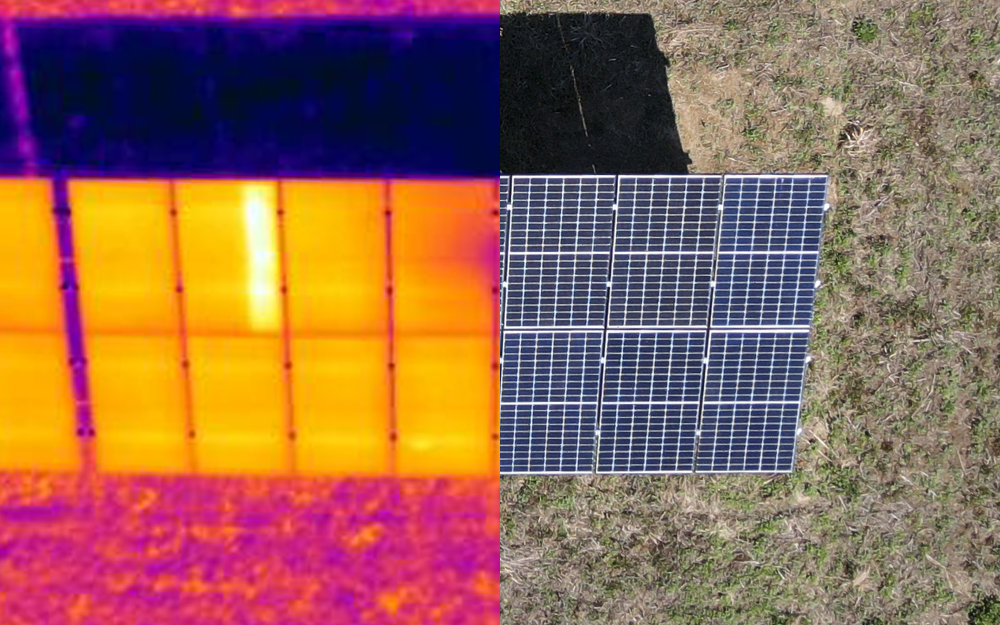

Expert Level Inspection

For detailed inspections with precise production impact analysis and expert reports adhering to top international

technical standards.

- Infrared imaging at 3cm/px

- RGB imaging at ~1cm/px

- Adheres to IEC TS 62446-3:2017 for data analysis and temperature measurement

- ITC Level 2 expert analysis and review

- AI prepared, human reviewed

- Energy loss calculation

- Anomaly classification based on normalized ΔT

Benefits:

- AI pinpoints cell-level anomalies, substring issues, module defects, diode failures, junction box concerns, potential PID, shading and structural damage.

- Precise anomaly classification based on normalized delta T

- Good for insurance premium reductions

- Valid for insurance and warranty claims

- Compliant with a number of country standards for required inspections

- Ability to export data outside of Solar Spy platform in a number of formats including Excel

- In addition to the AI anomalies detection, a Solar Spy technical expert (human) site-specific recommendations

Thin-Film Delamination

Solar Spy’s unique capability to assess delamination using AI-powered RGB image analysis, quantifying and calculating the extent of delaminated cells. Most accurate on the market.

- HD RGB imaging at ~0.5cm/px

- Delamination coverage calculation

- AI prepared, human reviewed

Benefits:

- AI pinpoints cell and module level delamination calculation precise coverage

- Valid for insurance and warranty claims. Our clients have successfully recovered multiple millions from manufacturers based on these reports

- Ability to export data outside of Solar Spy platform in a number of formats including Excel

- In addition to the AI anomalies detection, a SolarSpy technical expert (human) site-specific recommendations

Solar Spy Inspection Phases Across the Site Lifecycle

Commissioning

Early defect detection within modules and inverters, ensuring installation integrity and supporting investment security, reducing commissioning

losses by up to 10%.

Exploitation Period

Regular inspections highlight operational faults and environmental impacts, guiding maintenance and enhancing energy production.

Final Warranty Period

Identifies warranty-covered defects, enabling cost-effective module replacement and preserving asset value.

Selling/Buying Phase

Provides critical data on asset condition and performance, facilitating informed transaction decisions.